PET juice filling line

PET juice filling line

Specially designed for juice and pulp-containing beverages using hot-fill technology. SOKOS employs aseptic filling process and precise temperature control system to ensure product quality and extend shelf life. The production line features unique anti-drip filling valves, automatic reflux system, and CIP cleaning function, effectively addressing pulp blockage challenges. Supports quick changeover between various bottle types, delivering fully automated production from bottle blowing, filling, capping to labeling.

PET Bottle Juice Hot Filling Line

SOKOS‘s PET bottle juice hot filling line combines advanced technology, intelligent automation, and exceptional reliability to deliver outstanding production performance. Designed with precision and innovation, each system can be fully customized to suit the unique needs of juice and beverage producers, ensuring smooth operation and consistent product quality.

We offer complete turnkey solutions for non-carbonated drinks, including PET bottled juice, mineral water, purified water, and non-sparkling wine. Backed by over 15 years of industry expertise, patented technologies, and durable engineering, Reliable Machinery has earned the trust of beverage brands in more than 200 countries across Asia, the Americas, Europe, and Africa.

Production Capacity: 2,000–36,000 bottles per hour (500ml)

Applications:

Juice: fruit and vegetable juice, pulp juice, concentrated juice

Beverage: energy drinks, vitamin water, flavored juice, soft malt drinks, soda

Milk: soy, almond, chocolate, rice, oat, cultured buttermilk

Tea: green tea, black tea, milk tea, iced tea

Coffee: café latte, cappuccino, mocha

With SOKOS, you gain more than just equipment — you gain a trusted partner dedicated to boosting your productivity, maintaining product purity, and driving your beverage business forward.

KEY FEATURES OF JUICE LINE

This advanced hot filling machine is designed to handle a wide range of beverages, including juice, tea, milk-based drinks, liquid foods, energy drinks, milk tea, and coffee. It easily fills heat-resistant PET bottles ranging from 0.25L to 2.5L, with a production capacity of 1,000 to 24,000 bottles per hour—all with minimal spare part changes for maximum efficiency.

The fully automatic 3-in-1 juice filling system combines rinsing, filling, and capping in one compact unit. Equipped with a PLC control system and an intuitive touch screen interface, it ensures smooth operation and easy adjustment. The main structure is built from high-grade SUS304 or SUS316 stainless steel, while key electrical components are sourced from top international brands such as Mitsubishi, OMRON, and SIEMENS, guaranteeing stable and reliable performance.

With a high filling precision of ±1%, the machine maintains the beverage’s original color, flavor, and nutritional value. It ensures every bottle delivers freshness, quality, and visual appeal—offering consumers a healthy, refreshing, and satisfying drinking experience.

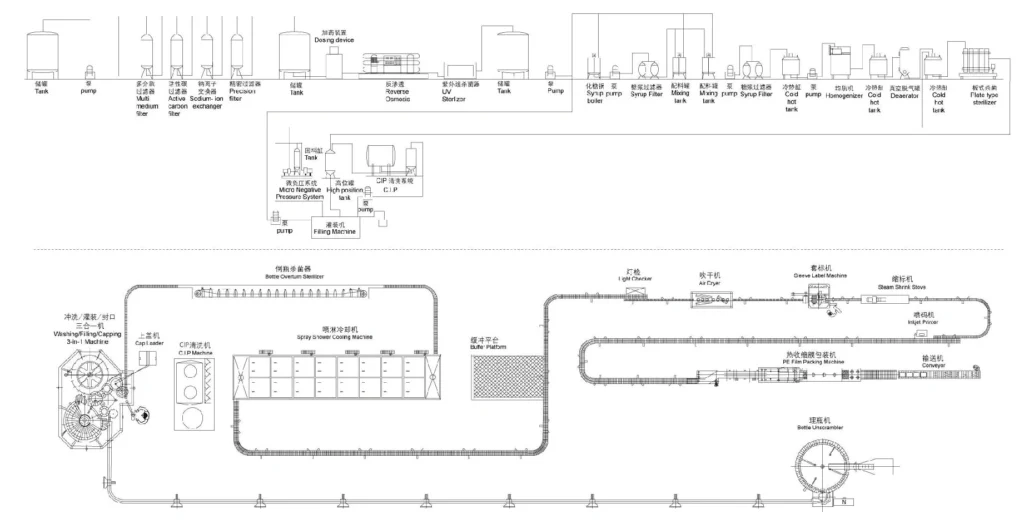

SOKOS delivers a complete juice filling line encompassing water treatment, blending, filling, packaging, and CIP cleaning processes. Utilizing hot-fill technology and sterile protection systems to ensure product quality and extend shelf life. Intelligent control enables precise coordination of all stages, while modular design allows flexible configuration, providing clients with an efficient and reliable turnkey solution.

Introduction to each module

OF JUICE PRODUCTION LINE

The SOKOS juice filling line adopts a modular overall design, intelligent control, and ensures aseptic operation throughout the process. The following is an introduction to each module:

Intelligent CIP Cleaning System

Precise temperature control with ±2℃ accuracy for stable cleaning process

Visual flow meters enable real-time monitoring of cleaning fluid velocity

Manual control valves integrated on panel for easy and direct operation

Intelligent cleaning time control system significantly improves efficiency

Optimized equipment layout saves space while enhancing cleaning performance

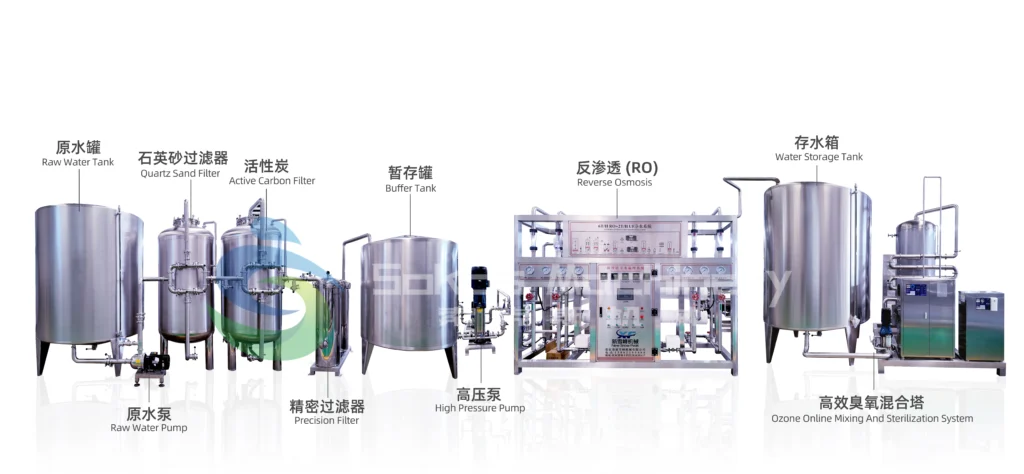

The upstream water treatment system

Employs multi-stage filtration (quartz sand + activated carbon + precision filtration) and dual reverse osmosis technology.

Equipped with UV sterilization and ozone sterilization devices to ensure water quality meets beverage water standards.

Intelligent online water quality monitoring tracks key indicators such as conductivity and pH in real time.

Blending Room Process Design

Fully enclosed stainless steel batching system, equipped with high-shear emulsifying tanks and homogenizers

Precisely temperature-controlled pasteurization device effectively inactivates enzymes and protects color

Modular piping design supports rapid switching between multiple formulations, reducing cross-contamination

Bottle Blowing Machine

SK series heat resistant bottle blow molding machine is suitable for producing PET plastic containers and bottles from 50-2000ml. It is widely used to produce the carbonated bottle, mineral water pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc.

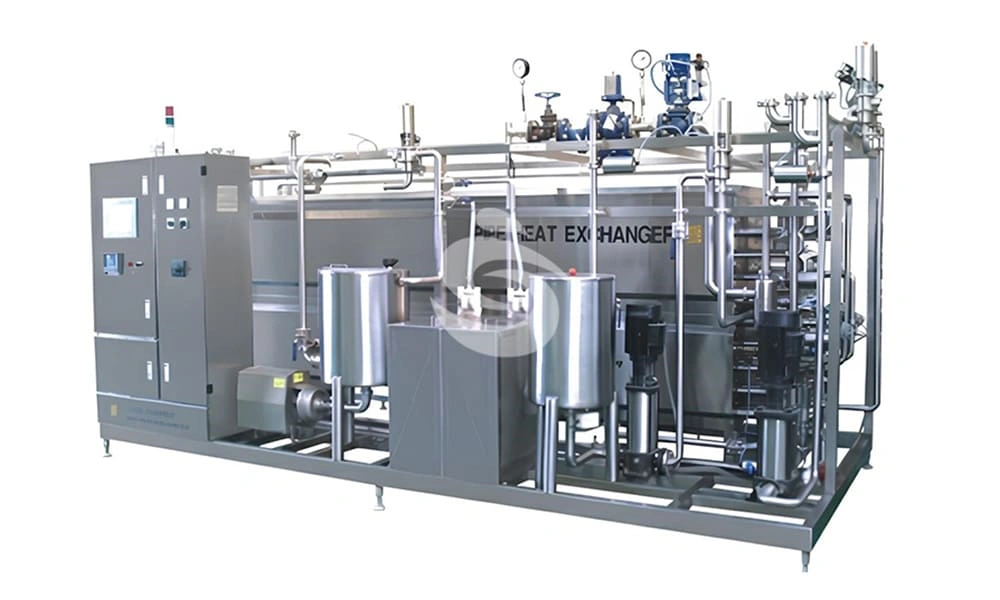

Plate sterilizer

Precise temperature control with ±1℃ accuracy for stable sterilization process

Optimized plate structure and flow channel improve thermal efficiency by 30%

PLC+touchscreen automatic control ensures precise temperature and process management

Multiple sterilization processes available for various products and capacities

- Advanced heat recovery system significantly reduces steam consumption

Tube sterilizer

±0.5℃ precision temperature control ensures uniform product heating

Multi-layer tube design delivers higher heat exchange efficiency

Intelligent PLC system enables real-time monitoring and adjustment

Expertly handles products with particles and high viscosity

- Special heat recovery design reduces energy consumption by 25%

Pasteurization system

±0.5℃ precision temperature control ensures sterilization efficacy and nutrient retention

Special heat recovery system reduces energy consumption by 30%

Fully automatic PLC system monitors and records all process parameters

Adjustable temperature and time settings for various product requirements

- Full stainless steel construction meets food-grade hygiene standards