PET carbonated drink filling line

PET Bottle Carbonated Drink Filling Line

Complete solution for washing, filling, and capping carbonated beverages with high precision.

BRIEF INTRODUCTION

The carbonated beverage market is constantly evolving — from cola, sprite, and soda to sparkling water, cocktails, and flavored drinks, new trends and packaging innovations keep emerging.

Carbonated drink filling machines must overcome multiple challenges, including precise temperature control for energy efficiency, minimizing foaming, ensuring accurate filling levels, preventing neck residue, and maintaining optimal CO₂ retention. King Machine addresses all these challenges with advanced technology and intelligent design.

Moreover, our versatile filling systems can handle multiple products — from water and carbonated beverages to hot-fill liquids — all within a single integrated machine.

BRIEF INTRODUCTION

| Full Automatic Complete Carbonated Drink 2000-36000bph Production Line | Carbonated Drink | |||

| Material | Shape | Filling volume | Filling level(mm) | Neck type |

| PET Bottle | Square or Round Bottle | 100-2000ml | Distance from bottle neck According request | As request |

| Adjustable specifications of the bottle type | ||||

(Middle Mould Base) Bottle diameter ≤105mm Bottle Height≤335mm Customers need to buy additional change-over parts for the different bottles. If using square bottles, then bottle separating system will be added. | ||||

| Juice Preparation | Fruit , Concentrate, Powder mixing ….. | |||

Want to know more specifications? Click to Contact!

Production Process

Water Treatment for CSD Manufacturing

Our multi-stage purification system eliminates impurities, organic matter, and microbial contaminants through processes including silica sand filtration, activated carbon absorption, and reverse osmosis, ensuring water quality exceeds international drinking standards for consistent carbonated beverage production.

Purify Process:

Raw water>Water pump>Silica sand filter>Active carbon filter>Sodium ion exchanger>High pressure pump>Reverse osmosis>Ozone generator>Water tank>Pure water

Bottle Blowing Machines for Carbonated Drinks

Automatic PET Bottle Blowing Machine is suitable for blowing PET bottles of various shapes, volume from 100 ml to 2000 ml, wide application for blowing water bottles, soda bottles, cola bottles. Bottle shapes are all customized and can be adjusted according to your requirements.

Blowing process:

1) Pre-form inlet controlling

2) Bottle pre-form heating controlling

3) Blowing technology controlling

4) Bottle check and outlet

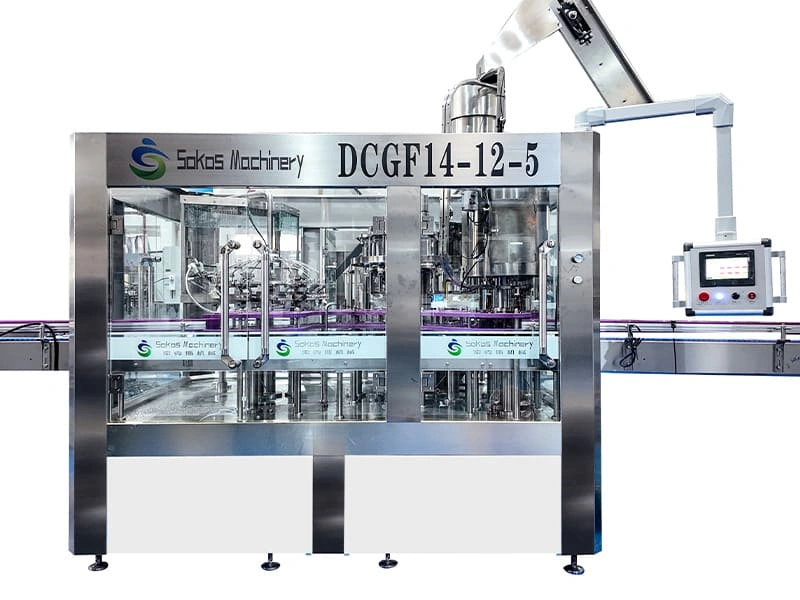

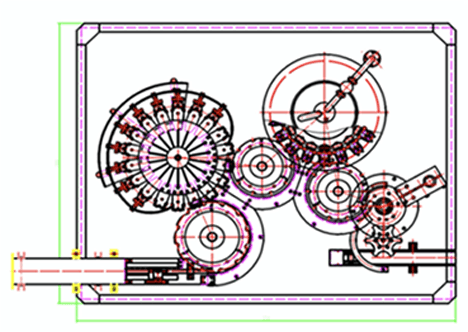

CSD Filling System

At the heart of the CSD production line, our triple-function machines perform simultaneous bottle rinsing, filling, and capping. The filling module employs counter-pressure technology to inject carbonated liquid while maintaining precise CO2 levels, minimizing foam formation. Food-grade stainless steel fillers automatically adjust to bottle height variations, achieving volumetric accuracy within ±1%. Downstream capping stations utilize servo-driven torque control to ensure airtight seals, compatible with both screw caps and press-on crown closures.

Labeling Machine

To address the unique challenges of labeling carbonated beverage bottles, we offer three distinct technologies: PVC sleeve labelers use steam-activated shrinking for 360° adhesion on chilled surfaces; OPP wrap-around systems apply pressure-sensitive labels via synchronized rotary mechanisms; while sticker labelers employ vacuum belts for precise positioning on curved containers. All variants incorporate anti-fog coatings to maintain label clarity in high-humidity environments typical of CSD production facilities.

Final Products Film / Case Packing Machine

Post-filling operations leverage two primary technologies: shrink wrapping machines encapsulate bottle groups in PE film using L-bar sealers and controlled-heat tunnels, while case packers automatically erect cartons, insert product groups, and apply adhesive closures. Both systems integrate with upstream production via photoelectric sensors, maintaining synchronization with the CSD filling line’s output rate to prevent bottlenecks.

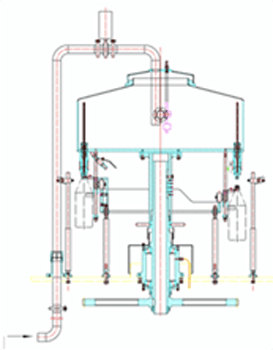

CSD Mixing System

The CSD mixing system formulates the production process according to the characteristics of different kinds of drinks. According to the formula of the beverage, the preparation process is designed.

It’s a complete system used to produce CSD beverages. It contains sugar melting tank, mixing tank, heating and cooling tank, sterilizer and so on. Depend on your different formulations, we can customize machines for you. Mainly used for pretreating. Best welding, polishing working with high quality stainless steel 304/316. Scientific process design. Automatic control.

Preparation process : Syrup melting machine > Syrup pump > Syrup filter > Mixing tank > Beverage pump > Double filter > Mixing tank > Double filter > UHT sterilizer > Homogenizer > CIP system

Production Process

This automatic three-in-one machine integrates bottle washing, filling, and capping into a single system. It offers a compact design, advanced control technology, and simple operation. With a modern PLC control system and intuitive touch screen interface, it ensures efficient and seamless man-machine interaction for stable production performance.

The washing section consists of key components such as a washing pump, bottle clamps, water distributor, turn plate, guide rail, protective cover, spraying system, drainage tray, rinse water tank, and water recycling unit—ensuring thorough cleaning and effective water utilization.

The filling section primarily consists of a filling tank, filling valves (operating under normal temperature and pressure), a filling pump, bottle support or hanging mechanisms, lifting devices, a liquid level indicator, pressure gauge, vacuum pump, and other essential components—ensuring precise, stable, and hygienic filling performance.

The capping section mainly includes capping heads, an independent cap loader, a cap unscrambler, a cap drop rail, a pressure regulator, and a cylinder. An external air compressor is also required as auxiliary equipment to ensure stable and reliable capping performance.