5 gallon Water Filling Line

5 gallon Water Filling Line

Integrates washing, filling, capping, and counting in one complete production line.

Home » 5 gallon Water Filling Line

5 gallon Water Filling Line

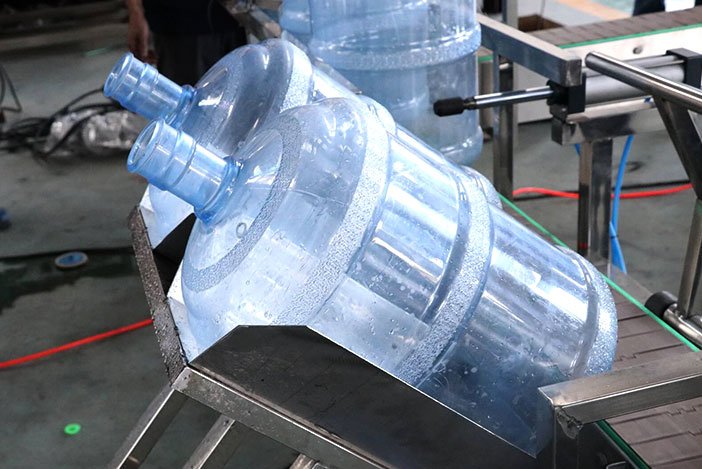

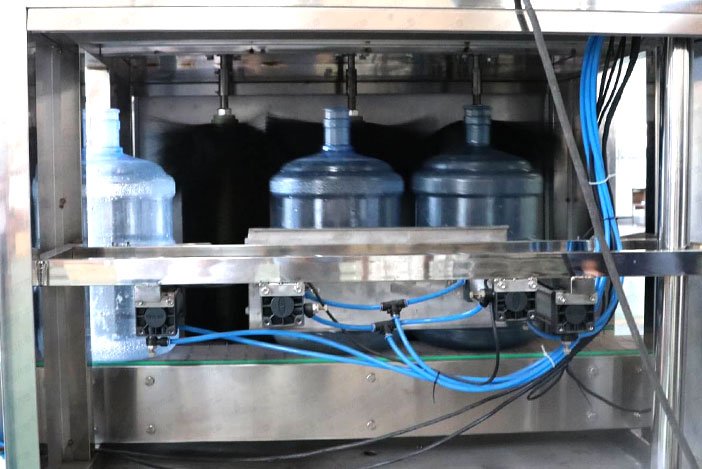

This filling line is specially designed for 3–5 gallon barreled drinking water, featuring the QGF series complete set of filling and packing machines. It integrates barrel washing, filling, and capping into a single unit, ensuring thorough washing and sterilization. The system can automatically handle barrel transportation, washing, sterilizing, filling, capping, counting, and product discharge. With its comprehensive functions, modern design, and high level of automation, it represents a new generation of automatic barreled water production lines, combining mechanical, electrical, and pneumatic technologies.

Production Capacity: 100–1200 BPH

Bottle Type: 10L–20L / 3–5 gallon barrels

At Reliable Machinery, customer satisfaction is our top priority. We provide full support throughout your production process — from installation and operation to maintenance and optimization — helping you build, maintain, and enhance the performance of your production line.

KEY FEATURES OF WATER LINE

Machine body and all pipes are made of stainless steel 304.

The motor for the cap unscrambles is from famous brand instead of simple stirring motor like others.

Strong stainless iron as the door stopper instead of the common magnet to make sure the doors will be safely opened and closed.

Additional High stability handle, exclusive with us.

The quality of both equipment and electrical parts reaches the international advanced level. This drinking water filling machine is running with high speed, high accuracy and high stability. The application of alarm devices for bottle jam, bottle shortage, bottle damage, cap shortage, overloading in several places ensure the safety of its production.

The sealer can seal bottle caps automatically. This 5 gallon filling machine with water spraying device to sterilize caps of bottles in order to ensure those caps are aseptic and healthy ,also this line can automatically carry out bottle feeding washing, sterilizing, filling capping, counting and products discharging .

Set red emergency stop button, strengthen security. Electric box is installed inside of the filling machine, saving more factory space. Latest conveyor cap loader reduces the occurrence of caps returning. Spare Parts Stock Service and 2 years warranty.

Description

The whole process is controlled by computer or PLC, high automatic.

Optional intelligent plant management software applicable to internet collects, transits, stores, statistics, and analyses real-time data making remote control and digitalized production management easy.

Optimized technology lowers running cost by cutting down consumption of water, electricity, and chemical material.

The design of complete line fully complies with regulation for food safety-quality by avoiding dead angle, dead-end, static liquid. thread connector, etc.

Extensively adopts adapter, manhole, valve, etc., to ensure the safety and easy maintenance.

Combination of mature technology and continuous innovation ensures stability and reliability.

ONTAINERS AND SPECIFICATIONS

| |||||||||||

| |||||||||||

| |||||||||||

Case

Project: 1200 Bottles/Hour 5 Gallon Barrel Water Production Line

Location: Oman

Commissioning:Reliable Machinery Team

Scope: Including

* Automatic 3 in 1 filling machine

* Semi-auto bottle blowing machine

* Date Code Printer

The whole production line has been running steadily, and the customer has occupied a great market share in Oman. We continue to provide equipment maintenance services. In the near future, this customer expects to be served by Reliable for capacity increase and new production line landing.