3-10L Water filling line

3L - 10L Water Filling Line

Efficient and hygienic solution for large-bottle drinking water production.

Home » 3-10L Water filling line

3L - 10L Water Filling Line

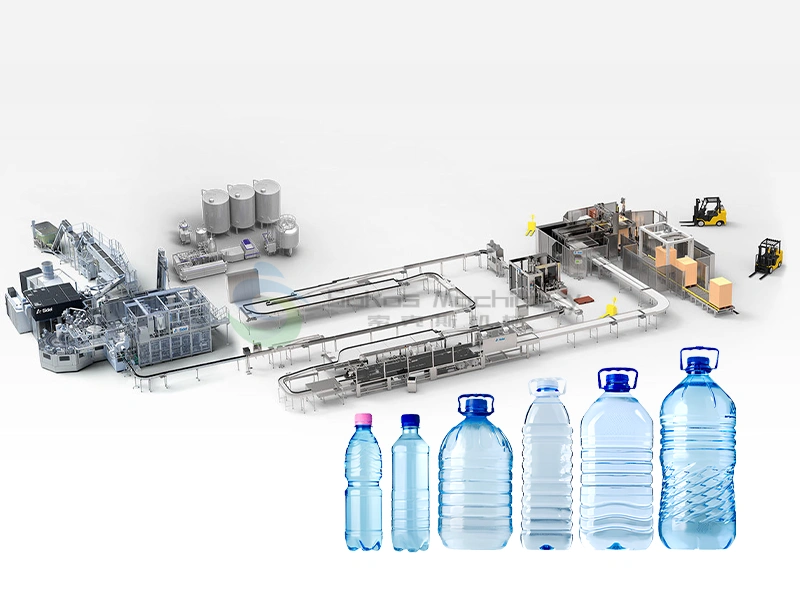

This filling line is designed for producing 3–10L plastic bottled mineral water, purified water, alcoholic beverages, and other non-carbonated drinks. It consists of a bottle blowing machine, water treatment system, water filling unit, and packaging system, among other components.

Specially engineered for large-bottle beverage production, the line features an advanced intelligent control system, stable filling and refilling performance, automatic bottle positioning, wide application range, and easy adjustment. The entire filling process is fully enclosed and contamination-free.

Production Capacity: 400–1200 BPH

Bottle Type: Plastic Bottle

At Reliable Machinery, customer satisfaction is our top priority. We provide full support in every stage of your production — from setup and operation to maintenance and optimization — ensuring your filling line runs efficiently and reliably.

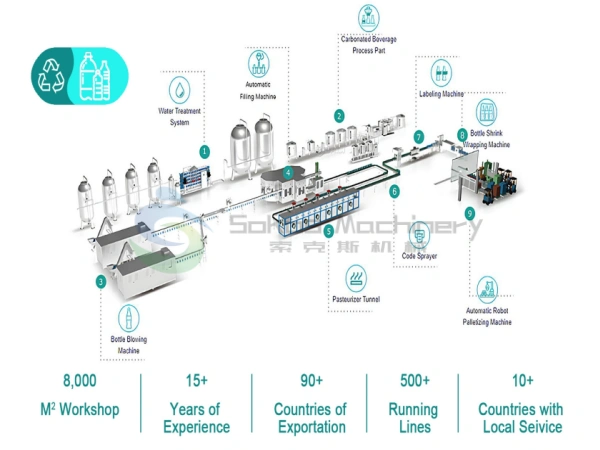

Production Process

Our complete production line includes a Water Treatment System, Bottle Blowing Machine, Filling System, Labeling Machine, and Final Products Film/Case Packing Machine, ensuring every step from water purification to final packaging is efficient and reliable.

Water Treatment System

This system efficiently removes turbidity, organic matter, iron, manganese, oxides, suspended solids, colloids, residual microorganisms, and certain heavy metal ions from water. It also reduces water hardness, ensuring that the treated water fully meets national standards for fresh drinking water, and even complies with mineral water quality requirements.

Purification Process:

Raw Water → Water Pump → Silica Sand Filter → Activated Carbon Filter → Sodium Ion Exchanger → High-Pressure Pump → Reverse Osmosis → Ozone Generator → Water Tank → Pure Water

Bottle Blowing Machine

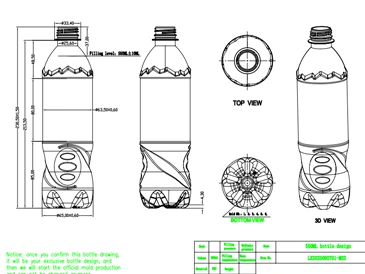

This stretch blow molding machine is specially designed for producing 3–10 liter PET bottles. It consists of a main unit and a rotary infrared heater. The infrared heater, with its high penetration capability, heats both the inside and outside of the preform evenly, ensuring uniform heating and superior bottle shaping quality. During production, the operator only needs to place the heated preform into the blow mold and press the switch — the computer system handles the entire process automatically.

Blowing Process:

Preform inlet control

Preform heating control

Blowing process control

Bottle inspection and outlet

Bottle Washing, Filling, Capping Machine

This machine works harmoniously with air-conveyor belt, It holds the bottles by the neck, thus, reducing the possibility of bottles falling over during conveying process.

This machine is used to fill carbonated drink into pet bottle and with screw caps capping function.

This machine integrated three function: 1. Rinse the empty pet bottle, 2. filling the rinsed bottles, 3. capping the filled bottles.

Bottle Labeling Machine

We offer several different types bottle labeling machine based on your requirement. Machines can be used for PVC sleeve label, self-adhesive label, OPP/BOPP label. Stainless steel Main Machine Frame / Famous electrical components (SIEMENS PLC controller ,Inverter ,Mitsubishi Motor)

Final Packing Machine

It adopts special safety coating, anti-sticking and high-temperature resistant alloy knife, equipped with imported detection photo electricity, which is easy to switch and choose. For thin and small packages, it can also easily complete the sealing and packaging operation. There is no need to worry about inaccurate temperature and damage to the product.

The sealing knife itself also has an automatic protection function, which effectively prevents miscutting the packaging. With automatic alarm function, the safety of the operator is greatly improved. The whole set of machines truly realizes the unmanned operation connection with the production line

Features

Capable to produce 3-10L large volume,easy operation on bottle adjustment by star wheel changes, realized filling volume change, high automation ensures smooth operation after bottle volume change. To achieve customer’s requirement, RELIABLE offers free bottle design service to assist client finish some ancillary work.

Machine body and all pipes are made of stainless steel 304. The motor for the cap unscrambles is from famous brand instead of simple stirring motor like others. Strong stainless iron as the door stopper instead of the common magnet to make sure the doors will be safely opened and closed. Additional High stability handle, exclusive with us.

The machine is a fully automatic intelligent linear filling machine, which adopts advanced computer PLC control, photoelectric sensing and electric air control. The full-color touch screen man-machine interface, through the touch screen on the device, can complete the setting of the filling amount and the number of filling heads and automatically fill, and the process basically realizes one-button operation.

High Efficiency and productivity machine performance, Successful solution and continuous orders with long-term cooperation partner, we make our machinery cover all over the overseas market ,hot sale in Africa and Middle East market.long service life and high safety level give more profits back to customer with its high profitability,We warmly welcome customers all over the world to visit our manufacture.

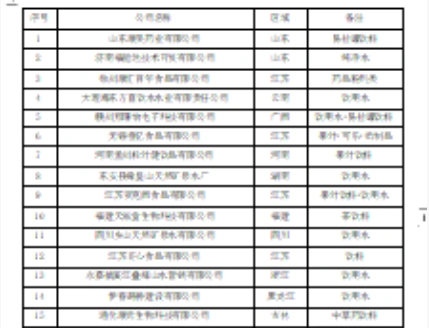

Successful Cases

Proven success delivering high-quality water solutions.

Project: 1000 Bottles/Hour 5L Pure Water Production Line

Location: Ghana

Commissioning: Reliable Machinery Team

Scope of Supply:

Water Treatment Equipment

Automatic Filling Machine

Adhesive Labeling Machine

Bottle Packing Machine

The entire production line has been operating smoothly, enabling the customer to capture a significant market share in Ghana. Reliable Machinery continues to provide ongoing maintenance support. In the near future, this customer plans to expand capacity and add new production lines, which will also be supported by Reliable Machinery.

Establish connection & joint hands

Reliable feasibility analysis

Attention to details & project process design

Closely tracking on production progress

Full set after-sales & installation adjustment

Continuous service & customer first

One-stop purchasing service