250ml-1L Water filling line

250ml-2L PET Bottle Water Filling Line

Efficient and hygienic solution for small to medium bottled water production.

Home » 250ml-1L Water filling line

Production Process

Our complete production line includes a Water Treatment System, Bottle Blowing Machine, Filling System, Labeling Machine, and Final Products Film/Case Packing Machine, ensuring every step from water purification to final packaging is efficient and reliable.

Water Treatment System

The water purification system effectively removes turbidity, organic matter, iron, manganese, oxides, suspended solids, colloids, residual microorganisms, and certain heavy metal ions from raw water. It can also reduce water hardness, ensuring that the treated water fully meets national standards for fresh drinking water and even the quality requirements for healthy mineral water.

Purification Process:

Raw Water → Water Pump → Silica Sand Filter → Activated Carbon Filter → Sodium Ion Exchanger → High-Pressure Pump → Reverse Osmosis → Ozone Generator → Water Tank → Pure Water

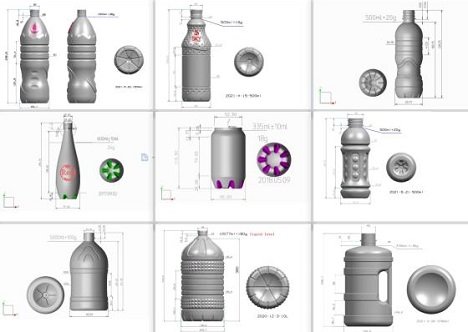

Bottle Blowing Machine

Automatic PET Bottle Blowing Machine is suitable for blowing PET bottles of various shapes, volume from 100 ml to 2000 ml, wide application for blowing water bottles, soda bottles, cola bottles. Bottle shapes are all customized and can be adjusted according to your requirements.

Blowing process:

1) Preform inlet controlling

2) Bottle preform heating controlling

3) Blowing technology controlling

4) Bottle check and outlet

Filling System

Reliable Machinery ace and top choice, medium & high capacity from 2000BPH to 36000BPH bottled water filling Machine for PET bottles.

Machine integrates the functions of rinsing, filling and capping together. Based on advanced technology overseas and designed according to the filling processing demands of mineral water, pure water, barrel jar water etc.

The main electric and air-drive components are from world famous brand. All control is advanced PLC touch-screen operation and realize people-computer dialogue operation.

Labeling Machine

It is used for applying labels to bottles after the filling process is completed. To meet different packaging needs, we offer various labeling options, including PVC shrink sleeve labels, self-adhesive labels, and OPP hot-melt glue labels.

We also provide free and attractive label design services, along with one-stop label sourcing, making the whole process easy and convenient. You are welcome to contact us for inquiries or customization.

Final Products Film / Case Packing Machine

It can automatically arrange, gather, and align PET beverage bottles or other similar containers, and then package them with shrinking film or cartons. The system is designed for the final group packing stage, making it suitable for various configurations such as 12 bottles per pack, 24 bottles per pack, and more. The entire process is automated, stable, and highly efficient.

Once packaged, the finished packs are tightly secured, neat in appearance, and easy to open for customers. Depending on production needs, you may choose between a shrink wrapper and a case packer, offering flexibility for different packaging styles and market requirements.

Capacity Introduction

Our filling machines come with various capacities to meet different production needs. If you require customization or higher output, please contact us for tailored solutions.

| Model | CGF8-8-3 | CGF14-12-4 | CGF18-18-6 | CGF24-24-8 | CGF32-32-10 | CGF40-40-12 |

|---|---|---|---|---|---|---|

| Capacity(500ML) | 2000-3000BPH | 3000-4000BPH | 6000-8000BPH | 8000-10000BPH | 12000-15000BPH | 16000-22000BPH |

| Floor area | 300㎡ | 400㎡ | 600㎡ | 1000㎡ | 2000㎡ | 2500㎡ |

| Total power | 100KVA | 100KVA | 200KVA | 300KVA | 450KVA | 500KVA |

| Opertor workers | 8 | 8 | 6 | 6 | 6 | 6 |

Features

The machine body and all pipelines are constructed from high-grade stainless steel 304.

The cap unscrambler is equipped with a branded motor, ensuring superior performance compared to ordinary stirring motors.

Durable stainless-steel door stoppers replace common magnetic types, providing secure and stable door operation.

Equipped with an additional high-stability handle — a unique feature exclusive to our machines.

To ensure bottles are smoothly and steadily transferred to the next stage of the production line, the entire flat bottle conveyor is enclosed with stainless steel side covers.

The conveyor belt is supported by precision rollers for stable and reliable operation.

Equipped with a high-quality water and oil separator from AIRTAC.

The control panel is supplied by SIEMENS, and all switches are from Schneider for superior reliability and performance.

Customized bottle shape design at no extra cost.

Full transparency in manufacturing progress tracking.

Industry-leading production environment with standardized operating procedures.

Strict selection of premium materials, precise craftsmanship, and extended service life.

High efficiency, energy saving, cost-effective, safe, and environmentally friendly.

Robust production capacity supported by advanced technology.

Comprehensive manufacturing and quality inspection systems.

Extended service life with lower maintenance costs.

Spare parts stock available and a 2-year warranty for reliable after-sales support.